Technology

What is Cseq?

Cseq is a unique decarbonisation technology and process that can be applied to any industrial plant, factory or power station where CO2 emissions are captured.

A working Cseq Pilot Plant has been developed in Melbourne, Australia and the technology and process is currently being optimised by the Project Team. It is anticipated that, following completion of a 3rd party verification process in August 2025, the project will move immediately into Digital Twin modelling and design of Cseq Plant modules and then to full commercialisation.

Cseq Global is selling Cseq decarbonisation licenses to industrial emitters to use its innovative decarbonisation technology and process, which can be applied to any industrial plant, factory or power station that produces and captures CO2 emissions, effectively making that factory or power station become carbon zero.

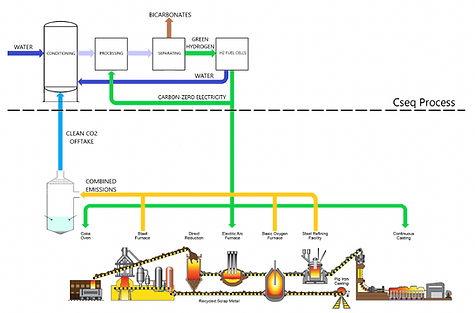

The Cseq process involves the installation of a modular Cseq plant alongside the industrial emitter, where captured CO2 emissions are fed into the plant, and the carbon is sequestered and converted to chemically safe and harmless bicarbonates and carbonates (which are valuable for a range of uses).

Essentially, the Cseq process takes captured CO2 emissions and utilizes the CO2 as a catalyst in a reaction with water that releases hydrogen ions. Subsequently, a process sequesters the carbon from the CO2 in bicarbonates and carbonates and then supplies the hydrogen ions to an electron source to generate hydrogen gas.

The bicarbonates and carbonates have high product value and the green hydrogen output from the Cseq plant can be used to generate carbon-zero electrical energy in an entirely circular closed loop, whilst delivering surplus electricity back to the factory and/or grid.

In the case of a gas-fired power station the green hydrogen can be blended with LNG to deliver high-yielding generation feed for carbon-zero electricity production.

In addition to making its emitting facility carbon-zero, the license to use the Cseq decarbonisation technology also provides the emitter source with substantial value-add opportunities via the production of low-cost green hydrogen, carbonates and bicarbonates. An additional sub-process within Cseq can take those bicarbonates/carbonates and process them further to produce pure carbon and a range of carbon variants that are valuable for a range of industrial uses.

The Cseq process/flowsheet (schematics)

Coal-fired power station

Green cement plant

Green steel plant

How does Cseq compare?

Sequestering captured CO2 via Cseq is far less costly than Carbon Capture & Storage (CCS):

-

As the captured CO2 does not need to be transported to a suitably certified storage site and injected underground;

-

Close to the source, captured CO2 is converted to become environmentally inert, harmless and useful;

-

This includes bicarbonates, carbonates and green hydrogen, all of which are valuable and can generate additional revenue streams outside the core activities of the emitter.

With respect to green hydrogen production, the Cseq process produces green hydrogen at a fraction of the cost when compared to current techniques. Specifically, green hydrogen production typically relies on electrolysis powered by renewable energy whereas via the Cseq process, water molecules are not split by high energy input (as is the case with electrolysis), but by the action of the CO2 input, requiring significantly lower amounts of energy.

As the Cseq process does not require osmosis filtered water, (which is the case for electrolysis), the amount of water consumed is also less and the cost of water is greatly diminished. Cseq can also use seawater!

In addition, via storage technology the Cseq generated hydrogen can be utilized within the Cseq plant allowing the process to be closed loop for both water and electricity usage, significantly reducing its operating cost.

Who needs Cseq?

Potential users of the Cseq technology are effectively any industrial emitter who must decarbonize their operations and/or become more sustainable (either via legislation or on a voluntary basis).

For instance:

-

Industrial facilities that capture CO2 but are having difficulty disposing of it in a safe and environmentally sound manner;

-

Those who implement CCS but have technical and/or logistical challenges with injecting CO2 underground;

-

Gas-fired power stations that wish to become cost-effective, carbon-zero electricity producers;

-

Coal-fired power stations that wish to become cost-effective, carbon-zero electricity producers;

-

Cement production facilities that wish to produce cost-effective green lime and green cement; and

-

Steel production facilities that wish to produce cost-effective green steel.